At TOS – Technical Outsource Solutions, our services extend beyond the production of individual components. We also provide assembly of components into complete products or modules. This allows us to offer you a single point of contact for the entire process—from raw materials and semi-finished parts to the final product, fully tested and ready for use.

Whether it involves small welded assemblies, precision components, or larger structures such as machine frames, we combine multiple techniques and processes into one high-quality solution. This approach helps you save time, reduce costs, and ensure an efficient process with reliable quality.

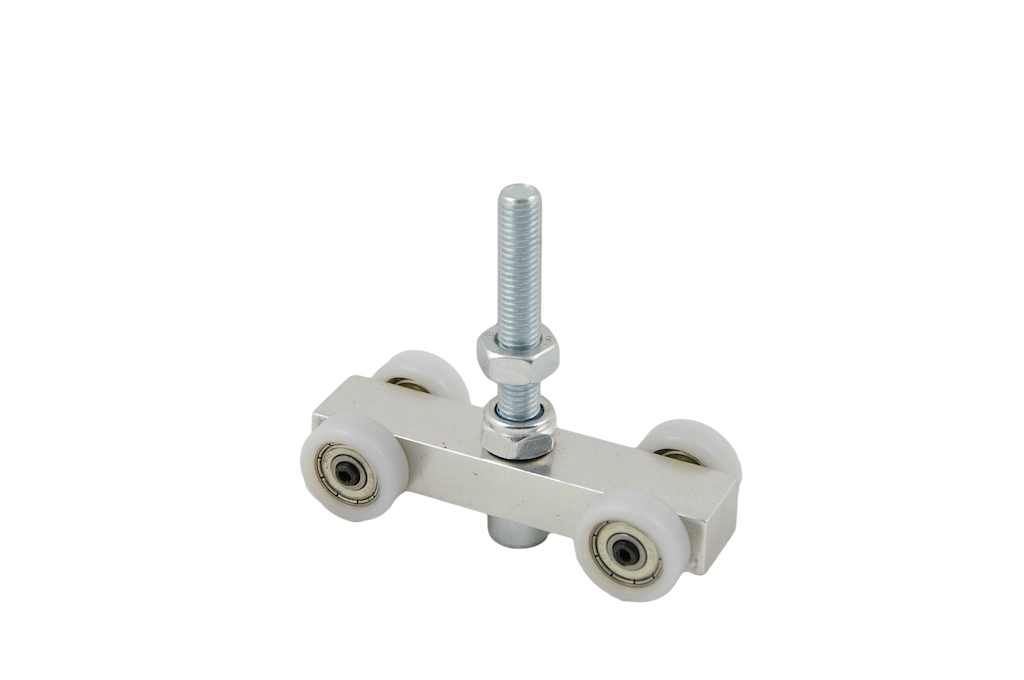

Assembly is the process of joining individual parts together to form a complete product or semi-finished product. This can range from simple assemblies with a few components to complex modules involving multiple materials and production techniques.

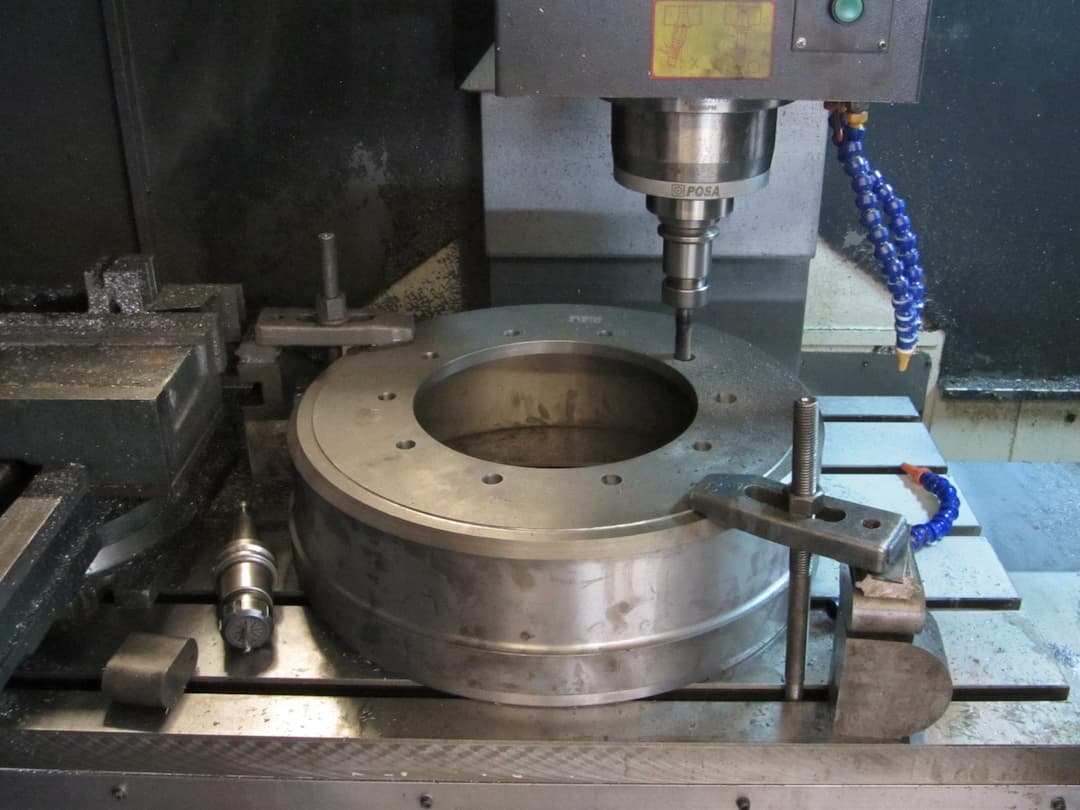

Because TOS has a wide range of in-house processing capabilities through our international network, we can seamlessly combine these processes. Consider, for example, parts produced via extrusion , high-pressure die casting , sand casting, gravity die casting , or lost-wax casting . We also integrate processes such as CNC machining , metal cutting , stamping , forging , deep drawing , and metal welding into a single assembly line.

After production, components can be surface-treated with powder coating , anodizing, or galvanizing . We then handle the complete assembly into a finished product, including packaging and delivery.

With this integrated approach, you benefit from shorter lead times, lower logistics costs, and guaranteed quality. TOS is your assembly partner: a single point of contact for the entire process, from component production to finished product.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start making a prototype.

After approval of the prototype, the assignment will begin.

At TOS, we offer complete solutions for assembling components, modules, and finished products. We combine technical expertise with efficient production methods, allowing us to assemble small and large series with consistent quality. From initial design to final delivery, we handle the entire process, including production, finishing, and logistics.

In addition to assembly, we also perform additional processes to fully finish the product. These include welding, drilling, bonding, and specific surface treatments such as powder coating , hot-dip galvanizing , or chrome plating . This ensures that every product is not only technically sound but also durable and aesthetically pleasing.

Every assembly is subjected to extensive quality controls . We perform both visual and dimensional inspections and verify functional properties. Upon request, we can provide reports, measurement certificates, and material declarations, ensuring complete transparency and traceability throughout the entire assembly process.

Finally, we ensure that the assembled products are packaged safely and according to customer specifications, are ready for export, and are delivered on time. We also support you with logistics solutions , inventory management, and just-in-time delivery. Our aftercare focuses on continuous improvement, so that future assembly projects run even more efficiently.

For one of our regular customers, we produced brake drums with an inner diameter of 500 mm, made entirely of....

For a client in the fruit and vegetable storage industry, we manufacture a wide range of products, ranging from welded....

Choosing TOS means choosing a partner who can manage the entire process in-house. We combine component production using techniques like extrusion, casting, CNC machining, stamping, or welding with high-quality assembly processes. This gives you a single point of contact that manages the entire chain: from engineering and component production to final assembly, packaging, and delivery. With our strict quality controls, flexible processes, and reliable partners, we guarantee consistent quality, competitive prices, and on-time delivery.