At TOS – Technical Outsource Solutions, we offer high-quality surface treatments such as powder coating. This durable finish protects metal parts from corrosion, wear, and weather, while giving the product a sleek and aesthetic appearance.

We advise you on choosing the right coating and color, tailored to your application and end use. Thanks to our international network of specialized coaters, we guarantee consistent quality, short delivery times, and competitive prices. With TOS, you have a single point of contact for the entire process: from production and coating to assembly and logistics.

Powder coating is an electrostatic painting process in which a fine powder is applied to the surface of a metal part. The powder adheres through static charge and is then cured in an oven. The result is a hard, wear-resistant, and even coating that is resistant to corrosion, scratches, and chemicals.

TOS uses powder coating for a wide range of applications: from industrial components and machine frames to consumer goods and design products. We offer a wide range of colors, gloss levels, and textures, allowing us to fulfill both functional and aesthetic needs.

In addition to powder coating, we coordinate the entire production process: from the fabrication of metal parts (such as CNC machining, cutting, or welding) to the final finishing. This ensures seamless integration of machining and surface treatment.

Thanks to our international network and technical support, you benefit from flexibility, quality, and scalability. TOS ensures that your products reach the market optimally protected and finished.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start creating a prototype.

After approval of the prototype, the assignment will begin.

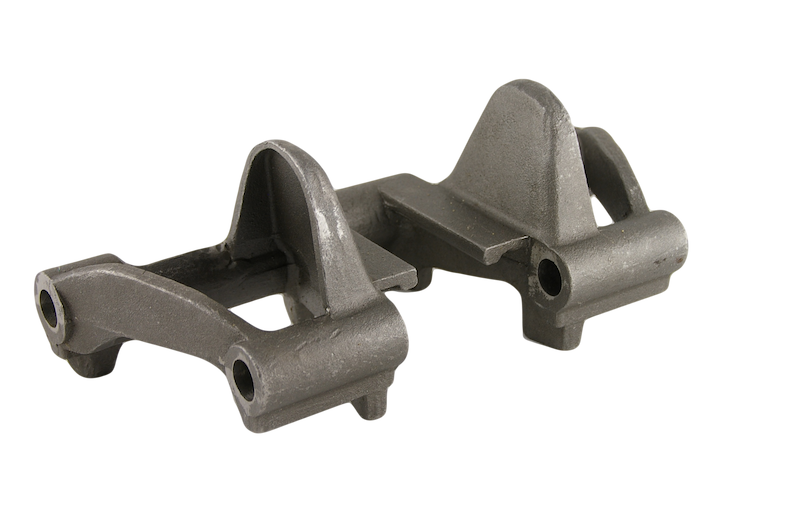

For a client focused on the restoration of historic military vehicles, we manufacture precision track links. These components are produced....

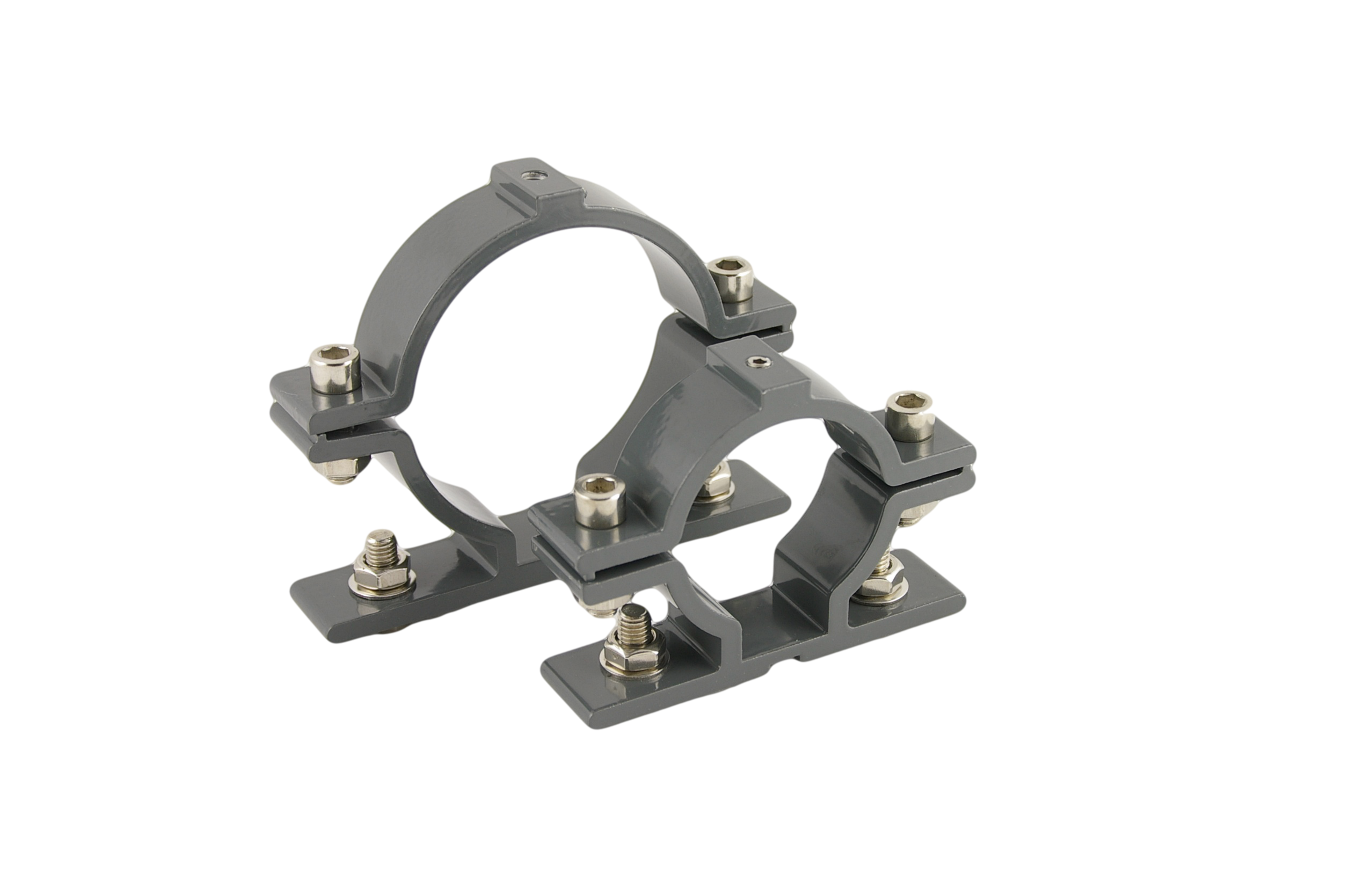

For a client in the infrastructure sector, we developed a sustainable aluminium extrusion clamp used for the installation of traffic....

Powder coating is more durable and wear-resistant, but wet painting can be more convenient for complex shapes or heat-sensitive materials.

Yes, we also provide wet painting, anodizing, galvanizing, chrome plating and other surface treatments.

TOS combines production and surface treatment in a single process, with guaranteed quality, speed and logistical support.