At TOS – Technical Outsource Solutions, we chrome-plate metal parts. This process gives a product a hard, glossy, and corrosion-resistant finish that is both functionally and aesthetically valuable. Chrome plating is used in sectors ranging from mechanical engineering and automotive to consumer goods and design.

We advise you on the correct layer thickness and finish, tailored to the application and appearance. Thanks to our international network of specialized chrome plating companies, we offer consistent quality , short delivery times, and competitive prices. With TOS, you choose a single point of contact that efficiently integrates production and chrome plating.

Chrome plating: durable protection with a high-gloss finish.

Chrome plating is an electrochemical process in which a thin layer of chromium is applied to a metal surface. This is done in an electrolytic bath, where chromium ions are deposited on the component by an electric current. The resulting chromium layer is hard, smooth, and highly wear-resistant, providing the base material with excellent protection against corrosion, oxidation, and mechanical stress.

Besides its functional benefits, chrome plating is known for its high-quality, reflective finish. The characteristic high gloss gives products a luxurious and professional look. Therefore, chrome plating is widely used in the automotive sector, but also for furniture, fixtures, design products, and various machine parts. Machined and stamped parts can be chromed effectively, provided the surface is suitable.

For a flawless finish, careful pretreatment is essential. The material must first be degreased, sanded, and polished to ensure a completely smooth surface. Imperfections, scratches, or porosity will remain visible through the chrome layer. The smoother the base material, the more beautiful and even the chrome finish.

There are two main forms of chrome plating:

At TOS Outsourcing, we manage the entire chrome plating process: from surface preparation and material selection to coordination of the chrome deposition, inspection, and quality control . Thanks to our international network of specialized chrome plating partners, we can produce both small and large series efficiently, accurately, and cost-effectively.

If there are still parts after chrome plating

With TOS, you are assured of a durable, high-quality, and visually perfect chrome finish, tailored to the technical and aesthetic requirements of your project.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start making a prototype.

After approval of the prototype, the assignment will begin.

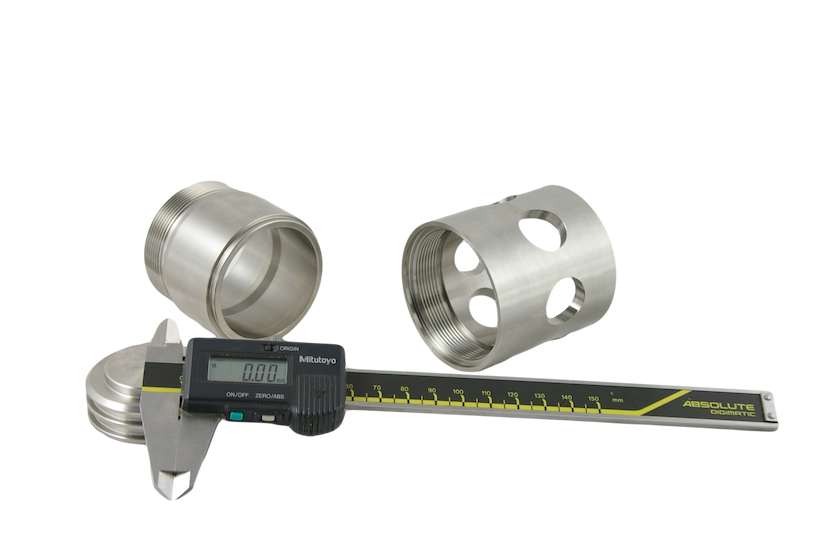

For a client in the cryogenics industry, we produce high-quality machined parts that must meet strict safety and temperature requirements.....

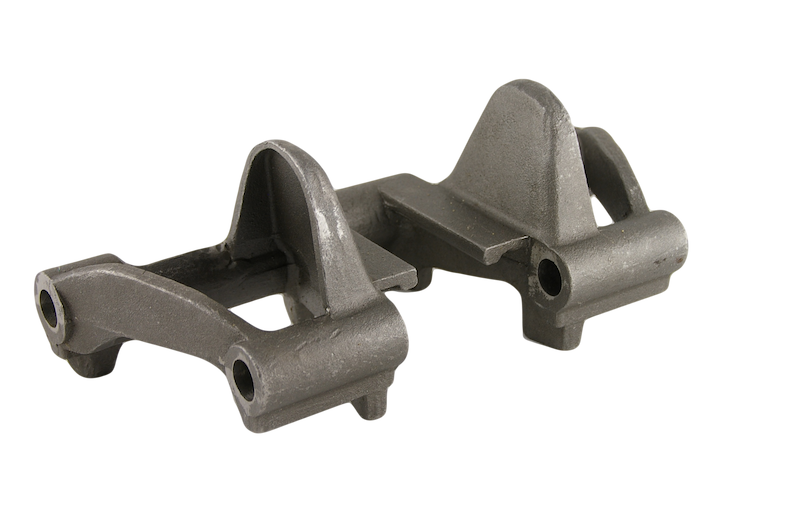

For a client focused on the restoration of historic military vehicles, we manufacture precision track links. These components are produced....

Chrome plating is an electrochemical process in which a thin layer of chromium is applied to a metal surface. This is done in an electrolytic bath where chromium ions are deposited on the component by an electric current.

The chromium layer forms a hard, smooth, and glossy surface that protects the metal from corrosion, oxidation, and wear. Chrome plating also provides a high-quality, mirror-like finish that is widely used in both technical and aesthetic applications.

The combination of protection and shine makes chrome plating a popular choice in a wide range of industries, from automotive to interior design.

There are two main forms of chrome plating, each with its own purpose:

Chrome plating always offers a suitable solution — whether for design products or highly stressed machine parts.

Chrome plating is widely used in both technical and decorative sectors. Common examples include:

The process is suitable for various metals such as steel, copper, brass and aluminium.

Chrome plating is known for its long life and durability. The chrome layer is extremely wear-resistant, corrosion-resistant, and resistant to high temperatures. This ensures long-term surface protection, even under harsh conditions.

A well-plated chrome part can last for many years without significant maintenance. It also retains its shine and smoothness, making chrome plating a sustainable investment for both functional and aesthetic applications.

At TOS Outsourcing , we manage the entire process from production to chrome plating, ensuring consistent quality and reliable delivery times.

We collaborate with specialized chrome plating partners in Poland and China, who have modern facilities and comply with European quality standards.

Our advantages:

With TOS you choose a durable, glossy and professional chrome finish that significantly extends the lifespan and appearance of your products.