At TOS – Technical Outsource Solutions, we offer hot-dip galvanizing as a high-quality surface treatment for steel and iron. This process involves immersing components in a bath of molten zinc, creating a thick, wear-resistant zinc layer. This layer provides long-lasting corrosion protection, even under harsh weather conditions.

Hot-dip galvanizing is particularly suitable for structures , fencing, and other outdoor applications where durability is essential. Thanks to our network of specialized partners, we guarantee consistent quality, competitive prices, and short delivery times. With TOS, you choose a single point of contact that efficiently combines production and galvanizing.

Hot-dip galvanizing is a process in which steel or iron components are fully immersed in a bath of molten zinc (approximately 450°C). During this process, the zinc reacts with the base material, creating a bonded zinc-iron alloy layer. This metallic bond provides strong, wear-resistant, and durable corrosion protection.

A key advantage of hot-dip galvanizing is its exceptional corrosion resistance. Even with prolonged exposure to moisture, rain, or the outside air, the steel remains optimally protected. This makes this treatment ideal for outdoor applications, such as:

The zinc layer also wears off evenly, so the protection remains effective for a long time — often for decades without maintenance.

Note: Hot-dip galvanizing is not the same as shot blasting. Shot blasting (also known as metallizing) involves applying molten zinc or aluminum to the surface using a spray gun, without immersing the product. Hot-dip galvanizing, on the other hand, provides complete and even coverage, even in hard-to-reach corners and cavities, thus offering better, longer-lasting protection.

Hot-dip galvanizing and powder coating are an excellent combination for extra durable protection. Hot-dip galvanizing provides strong, long-lasting corrosion resistance, while powder coating offers an aesthetic and wear-resistant finish. Combining both techniques creates a high-quality duplex coating that significantly extends the product’s lifespan and provides optimal protection against weather, wear, and chemical influences. Ideal for metal products that are used intensively or remain outdoors for extended periods.

At TOS Outsourcing, we manage the entire process : from pretreatment and material selection to galvanizing, inspection, and logistics. Thanks to our international network of reliable galvanizing plants, we can galvanize both small and large series efficiently and cost-effectively.

This ensures a durable, high-quality, low-maintenance finish that significantly extends the lifespan of your products.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start creating a prototype.

After approval of the prototype, the assignment will begin.

For a client in the packaging industry, we produce complete, custom-made machine frames that serve as the foundation for high-quality....

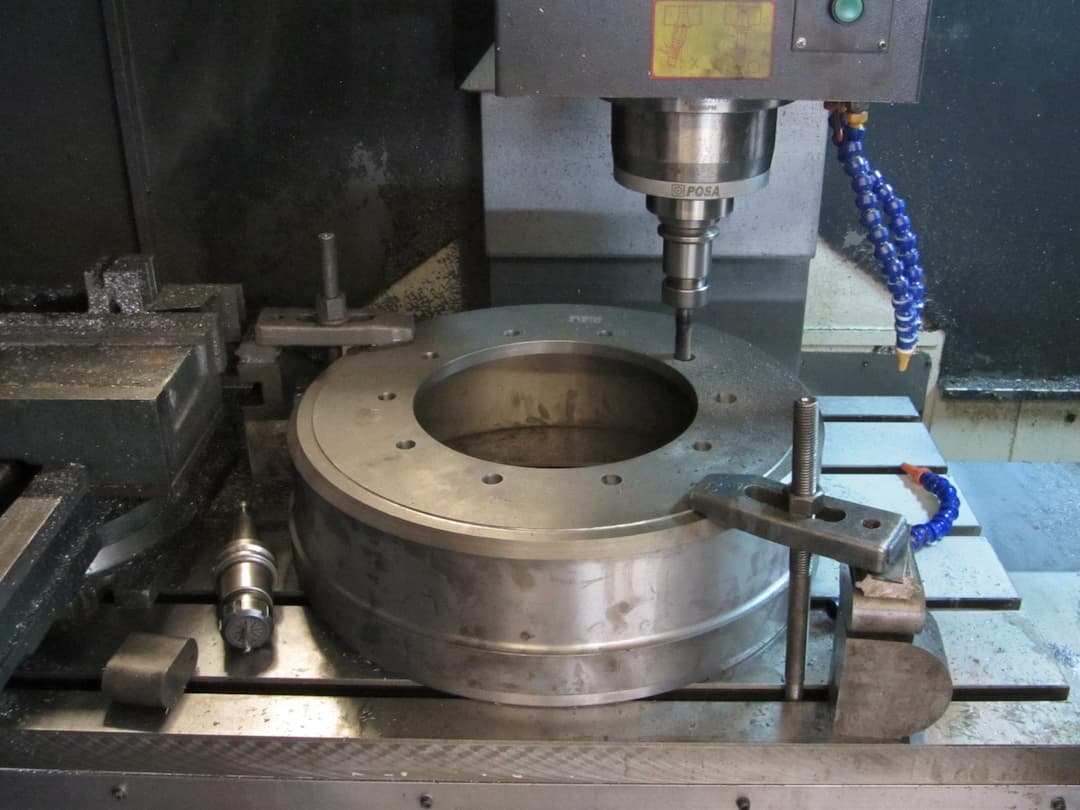

For one of our regular customers, we produced brake drums with an inner diameter of 500 mm, made entirely of....

Hot-dip galvanizing is a durable surface treatment in which steel or iron is immersed in a bath of molten zinc (approximately 450°C). During this process, the zinc metallically bonds to the surface, forming a wear-resistant, corrosion-resistant protective layer.

The zinc layer prevents oxygen and moisture from coming into contact with the steel, effectively preventing rust formation.

The result is low-maintenance, long-lasting protection that is ideal for structures exposed to the elements.

Hot-dip galvanizing of steel is primarily used for outdoor structures and components exposed to the elements for extended periods. Some typical applications include:

Thanks to its robust protection against rust and wear, hot-dip galvanizing is a reliable choice for outdoor applications where durability and low-maintenance use are important.

The lifespan of a hot-dip galvanised coating depends heavily on the environment in which the steel is located, but it generally provides protection for decades.

Hot-dip galvanizing is therefore one of the most durable forms of corrosion protection, without the need for regular maintenance or recoating.

Although hot-dip galvanizing and galvanizing both aim to protect steel from rust, the processes differ significantly:

The result is that hot-dip galvanizing is more durable and more resistant to mechanical stress. Galvanizing is primarily used for smaller components or indoor applications, while hot-dip galvanizing is preferred for large structures and outdoor applications.

At TOS Outsourcing, you choose a complete solution for hot-dip galvanizing, including production, surface treatment, and logistics . We manage the entire process – from fabrication and steel preparation to galvanizing, quality control , and delivery.

Thanks to our reliable partners in Poland and China, we combine European quality standards with competitive rates and short lead times.

With TOS you are assured of:

In short: TOS offers a sustainable and cost-efficient solution for hot-dip galvanizing steel, fully tailored to your project.