At TOS – Technical Outsource Solutions, we offer blasting as an effective surface treatment for metal parts. Blasting cleans, degreases, and removes rust, mill scale, and old coatings from the surface. The result is a clean, rough surface that’s perfectly suited for further treatments such as powder coating, wet painting, or galvanizing.

We advise you on the correct blasting method and grain size, tailored to your material and application. Thanks to our network of specialized blasting companies, we guarantee consistent quality, short delivery times, and competitive prices. With TOS, you choose a single point of contact that efficiently integrates production and surface treatment.

Blasting is a mechanical process in which small particles (such as corundum, glass beads, or steel grit) are sprayed under high pressure onto the surface of a workpiece. This removes contamination, oxidation layers, mill scale, or old paint layers. At the same time, the surface acquires a uniform roughness that ensures optimal adhesion of coatings, paints, or metallic finishes.

There are various blasting techniques, depending on the desired result. For example, coarse blasting can be used to remove heavy corrosion and rust layers, while fine blasting or glass bead blasting is used for a smooth, decorative surface. Blasting can also create a matte or satin finish, which is often used with stainless steel or aluminum.

At TOS, we tailor the blasting method to your specific product and application. We manage the process from pretreatment to final finishing and often combine blasting with other processes such as powder coating, wet painting, or anodizing. Thanks to our network of specialized partners, we can blast both small and large series efficiently and cost-effectively. This ensures optimal preparation and a high-quality final finish.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start creating a prototype.

After approval of the prototype, the assignment will begin.

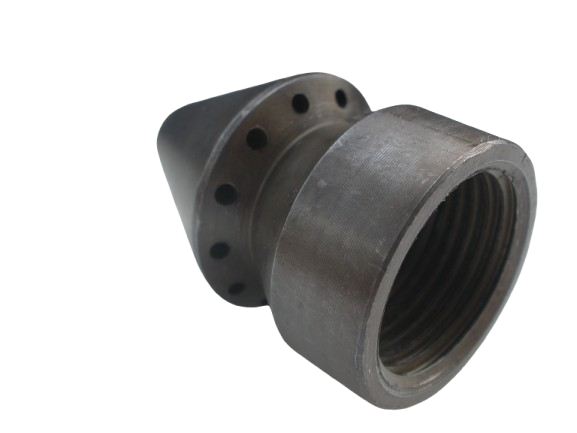

For a client specializing in self-propelled sprayers, we manufacture special spray nozzles that must withstand high pressure, chemical loads, and....

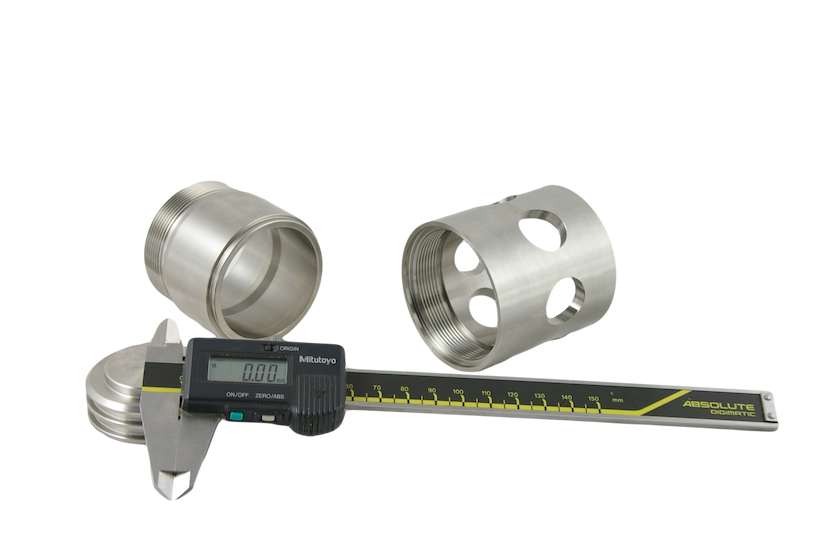

For a client in the cryogenics industry, we produce high-quality machined parts that must meet strict safety and temperature requirements.....

Blasting is a surface treatment in which a surface is cleaned under high pressure with an abrasive such as steel grit, corundum, or glass beads. This process removes rust, paint, mill scale, or other impurities, leaving the metal with a clean, rough, and smooth surface.

Blasting metals is often used in preparation for further treatments such as powder coating , wet painting, or galvanizing. It ensures optimal adhesion and extends the life of the final coating.

Metal blasting is suitable for a wide range of materials. The most common are:

Depending on the material and desired finish, a specific blasting medium and blasting pressure are selected. This way, TOS can always guarantee the right result, from coarse cleaning to fine decorative work.

Blasting of metals is used for various purposes:

The process is indispensable in sectors such as mechanical engineering, construction , automotive and industrial manufacturing, where quality and sustainability are central.

The difference between coarse blasting and glass bead blasting lies in the abrasive used and the purpose of the treatment:

At TOS, the correct blasting method is selected based on the material type, desired roughness and application.

TOS offers a complete solution for metal blasting – from preparation to final finishing. Thanks to our carefully selected production partners in Poland and China, we can combine quality, speed, and cost-efficiency.

We coordinate the entire process :

With TOS as your partner, you’re assured of a perfectly blasted surface, perfectly prepared for further processing or a durable finish.