At TOS – Technical Outsource Solutions, we provide high-quality surface treatments such as wet painting. This versatile technique allows you to apply a durable and aesthetic protective layer to metal and non-conductive materials. Wet painting offers flexibility in colors, gloss levels, and layer thicknesses, making it suitable for a wide range of applications.

We guide you through the selection of materials, the desired look, and the technical specifications. Thanks to our international network of specialized coating companies, we combine quality with competitive prices and short delivery times. With TOS, you choose a single partner that efficiently integrates production and surface treatment.

Wet painting is a surface treatment in which liquid paint is applied to a component, usually using spray techniques. The process begins with careful pretreatment, such as cleaning, sanding, or blasting, to ensure optimal adhesion. The paint is then applied in several thin layers, which, after drying or curing, provide a smooth and even finish.

The advantage of wet painting is its great flexibility. Unlike powder coating, wet painting can be applied to both metals and non-conductive materials, such as plastic or wood. There are also virtually unlimited possibilities in terms of color, gloss level, and layer thickness. This makes the technique ideal for both functional protective layers and high-quality aesthetic finishes.

At TOS, we coordinate the entire wet-painting process: from preparation and application to drying and quality control. Thanks to our collaboration with specialized partners, we can efficiently paint both small and large series. This guarantees that your products receive durable protection and the desired appearance, fully tailored to their application.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start creating a prototype.

After approval of the prototype, the assignment will begin.

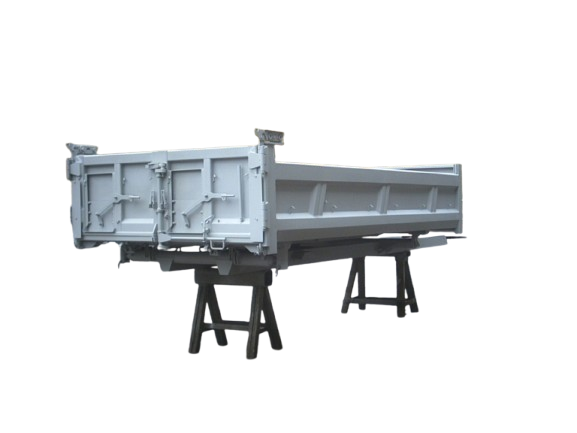

For a client in the heavy transport sector, we produced an iron wheel for high-load trailers, sand-cast in GG25 gray....

For a client in the earthmoving sector, we produced a series of high-quality forged towing eyes. The heads of these....

The main difference between wet painting and powder coating is in the application and the end result.

In short: wet painting is the right choice when versatility, detail and customisation are important.

With TOS Outsourcing, you choose quality, reliability, and complete peace of mind. We manage the entire wet-painting process: from preparation and surface treatment to final inspection and delivery. Thanks to our carefully selected partners in Europe and Asia, we guarantee consistent quality, competitive prices, and short lead times. TOS ensures that your products are delivered perfectly painted and ready to use—according to European quality standards.