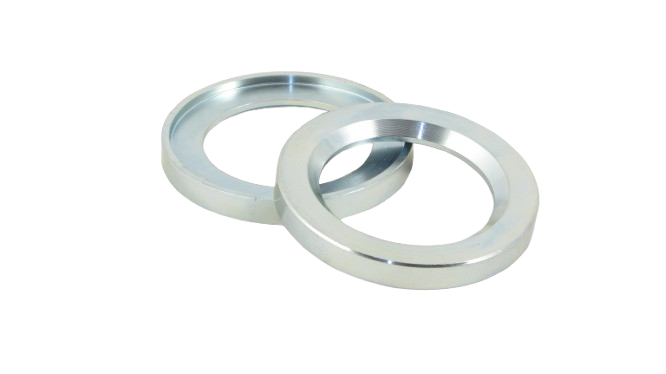

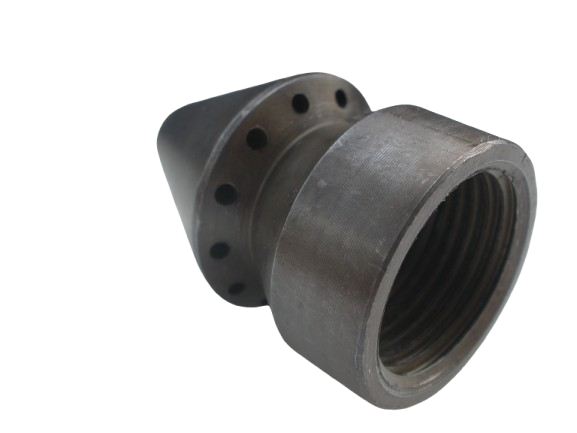

At TOS – Technical Outsource Solutions, we provide galvanization of metal parts. This electrochemical surface treatment applies a thin layer of zinc or nickel to steel, copper, or other metals, protecting the product against corrosion and wear.

Galvanizing can be applied for both functional and aesthetic purposes: from a protective zinc coating to a glossy, decorative finish. Thanks to our international network of specialized galvanizing companies, we guarantee consistent quality, competitive prices, and short lead times. With TOS, you choose a single point of contact that efficiently integrates production, galvanizing, and any post-processing.

Electroplating is an electrochemical process in which a metal is immersed in a bath containing a solution of metal ions. By applying an electric current, the ions adhere to the surface, forming a thin, even layer. Depending on the type of metal chosen—such as zinc, nickel, or chrome—the component acquires specific properties.

Zinc galvanizing offers excellent rust protection and is widely used in the construction and machinery industries. Nickel galvanizing creates a hard, smooth, wear-resistant and corrosion-resistant coating, often serving as a base coat for other finishes. Galvanizing can also serve an aesthetic purpose, for example, for glossy or matte finishes in consumer applications.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start making a prototype.

After approval of the prototype, the assignment will begin.

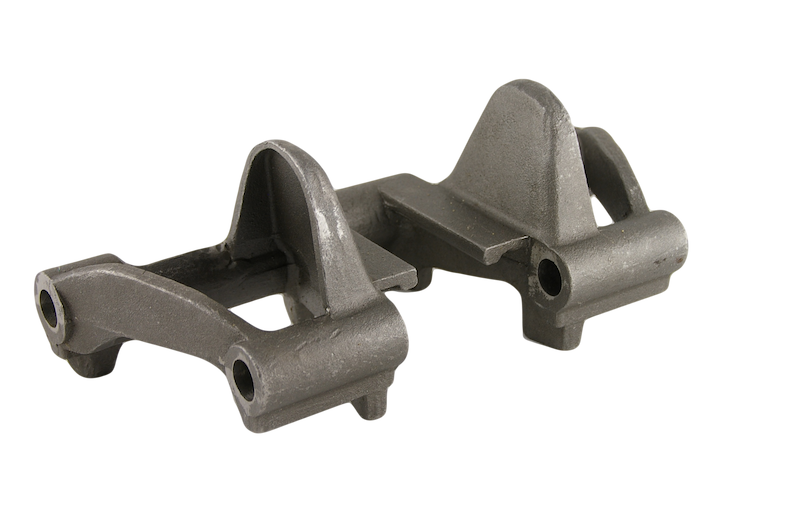

For a client focused on the restoration of historic military vehicles, we manufacture precision track links. These components are produced....

For a client specializing in self-propelled sprayers, we manufacture special spray nozzles that must withstand high pressure, chemical loads, and....

Galvanizing, also called electrolytic galvanizing, is an electrochemical process in which a thin layer of metal—usually zinc, nickel, or chrome—is applied to a metal component.

The component is immersed in an electrolytic bath and connected to an electric current. This causes positive metal ions to deposit on the component’s surface, creating a smooth, even, and corrosion-resistant metal coating.

This process is often used to protect steel, copper, or brass from rust and wear, but also to give the product a decorative finish. Galvanizing is a precise and controlled method, allowing the coating thickness and appearance to be precisely tailored to the application.

Galvanizing or electrolytic galvanizing can be applied to various types of metals, depending on the desired end result:

Thanks to the versatility of the process, galvanizing can be used for functional protection or a high-quality visual finish.

Although galvanizing and hot-dip galvanizing both provide a zinc layer to protect against rust, the processes differ greatly in execution and result:

Feature | Galvanizing (Electrolytic galvanizing) | Thermal galvanizing |

Process | Electrochemical, in liquid electrolyte | Immersion in molten zinc (±450°C) |

Layer thickness | Dun (5–25 µm) | Thin (50–150 µm) |

Finishing | Smooth, glossy or matte | Thicker and coarser surface |

Application | Indoor use, decorative, precision engineering | Outdoor use, robust protection |

Galvanizing is therefore ideal for parts with high dimensional accuracy or decorative requirements, while hot-dip galvanizing is chosen for durable outdoor protection.

Yes, galvanizing is used not only as a protective layer but also as a decorative finish. By using different metals, such as nickel, chrome , or copper, components can be given a glossy, matte, or even colored appearance.

Therefore, electrolytic galvanizing is often used in sectors where both appearance and protection are important—think designer products, automotive parts, fixtures, or interior components.

In addition, the controlled layer thickness makes it possible to create a very smooth and tight surface, which is ideal for visible work.

At TOS Outsourcing, we manage the entire process from production to surface treatment, including electrolytic galvanizing and galvanizing.

We collaborate with carefully selected partners in Poland and China, allowing us to combine quality, speed, and cost-efficiency.

Our advantages:

With TOS you choose a durable, sleek and professional metal finish that meets the highest industrial and aesthetic requirements.