At TOS – Technical Outsource Solutions, we offer electrocoating (also called e-coating) as a durable and consistent surface treatment. During this process, a water-based paint layer is electrostatically applied to metal parts and then cured in an oven. The result is a thin, even, and corrosion-resistant coating, ideal as a primer or topcoat.

Electrocoating is suitable for both small parts and large structures and is often used in the automotive and mechanical engineering industries. Thanks to our network of specialized partners, we guarantee consistent quality , competitive prices, and short delivery times. With TOS, you choose a single point of contact that efficiently integrates production and e-coating.

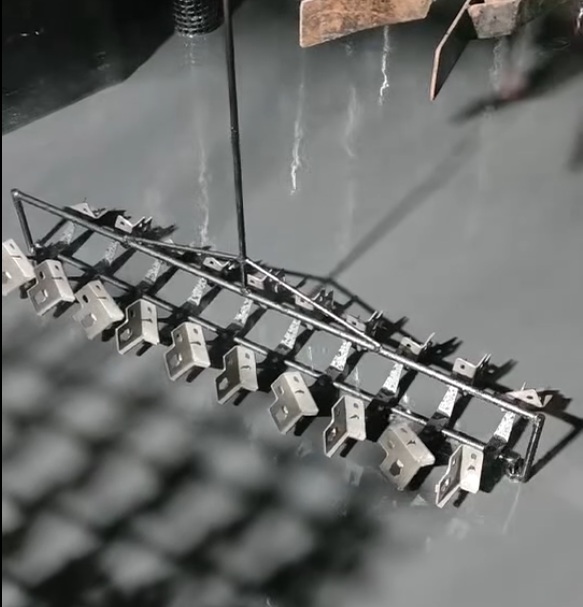

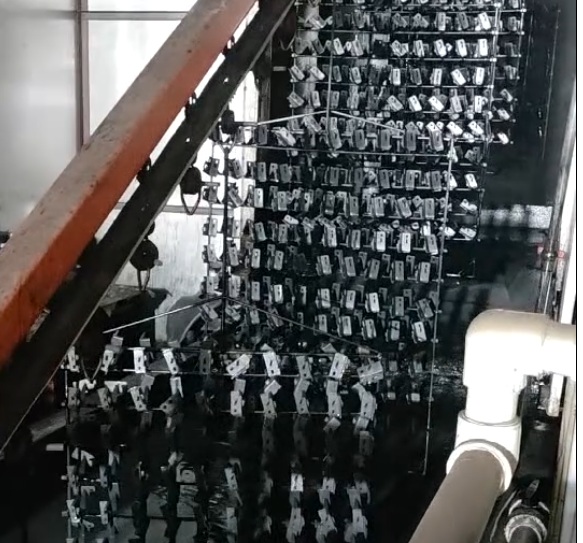

Electrocoating, also known as e-coating, is an advanced electrostatic coating process in which metal parts are fully immersed in a bath of water-based paint. By applying an electric current, the paint particles adhere evenly to the entire surface – even in hard-to-reach areas such as seams, cavities, and sharp corners. After the dipping process, the coating is cured in an oven, creating a hard, smooth, and durable layer that provides long-term protection against corrosion.

A key advantage of electrocoating is its excellent coverage and corrosion resistance with a relatively thin layer thickness. This makes e-coating ideal as a base coat or primer for subsequent treatments such as powder coating or wet painting. TOS frequently uses e-coating on welded structures , stamped parts , cut sheet metal , and deep-drawn parts , which are optimally protected by the full immersion process and even layer buildup.

The combination of e-coating and powder coating produces an extremely strong, wear-resistant finish with high rust protection, even in salty or humid environments. E-coating can also be applied as a top coat, usually in black or neutral base colors, for a functional and sleek appearance.

At TOS, we are happy to advise you on the optimal application of electrocoating, tailored to your product, industry, and desired appearance. Thanks to our international network of specialized coaters in Europe and Asia, we can efficiently process both small and large series. Furthermore, we often combine e-coating with powder coating . This guarantees a high-quality, durable, and aesthetic finish that perfectly matches your technical and visual requirements.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start making a prototype.

After approval of the prototype, the assignment will begin.

For a client who supplies construction fences, we produce a wide range of construction fence clamps in various sizes and....

For a client in the fruit and vegetable storage industry, we manufacture a wide range of products, ranging from welded....

Electrocoating, also known as e-coating , is an advanced electrostatic process that uses an electric current to apply an extremely thin and even layer of paint to metal surfaces. The product is immersed in a conductive paint solution, after which the paint particles adhere evenly to the metal. After application, the coating is cured in an oven, resulting in a very strong, corrosion-resistant, and durable layer.

E-coating is widely used in the automotive industry, mechanical engineering, and metalworking, where stringent demands are placed on protection and quality. It also often serves as a primer for subsequent surface treatments such as powder coating and wet painting . Thanks to its excellent coverage—even in cavities and hard-to-reach areas—e-coating is ideal for complex metal parts.

The main difference is the layer thickness and finish. E-coating provides a thinner, tighter, and very even protective layer, while powder coating offers more variety in colors, gloss, and textures. Therefore, e-coating is often used as a base coat and powder coating as an aesthetic topcoat.

Yes, electrocoating can certainly be used as a topcoat. In that case, black, gray, or other base colors are often chosen. The coating then provides a functional, wear-resistant, and corrosion-resistant finish. For a more decorative result, an additional coating—such as powder coating or wet paint —can be added.

TOS manages the entire process, from production to surface treatment. Thanks to our close collaboration with specialized partners, we effortlessly combine electrocoating with other processes such as powder coating and wet painting.

If the part is an assembly of parts that are chrome-plated or galvanized in addition to the coating, this is also no problem at TOS.

In this way, we deliver a complete, sustainable and high-quality end result that meets European quality standards, fully integrated into an efficient supply chain that perfectly matches your needs.