At TOS – Technical Outsource Solutions, we anodize aluminum parts. This electrochemical process creates a hard oxide layer on the surface that is wear- and corrosion-resistant. Anodizing can be done in either transparent or various colors, offering both functional and aesthetic benefits.

We also offer hard anodizing for applications requiring increased wear resistance and oxide layer thickness. Thanks to our network of specialized anodizing companies, we guarantee consistent quality, short lead times, and competitive prices. TOS combines production and surface treatment into a single, complete process.

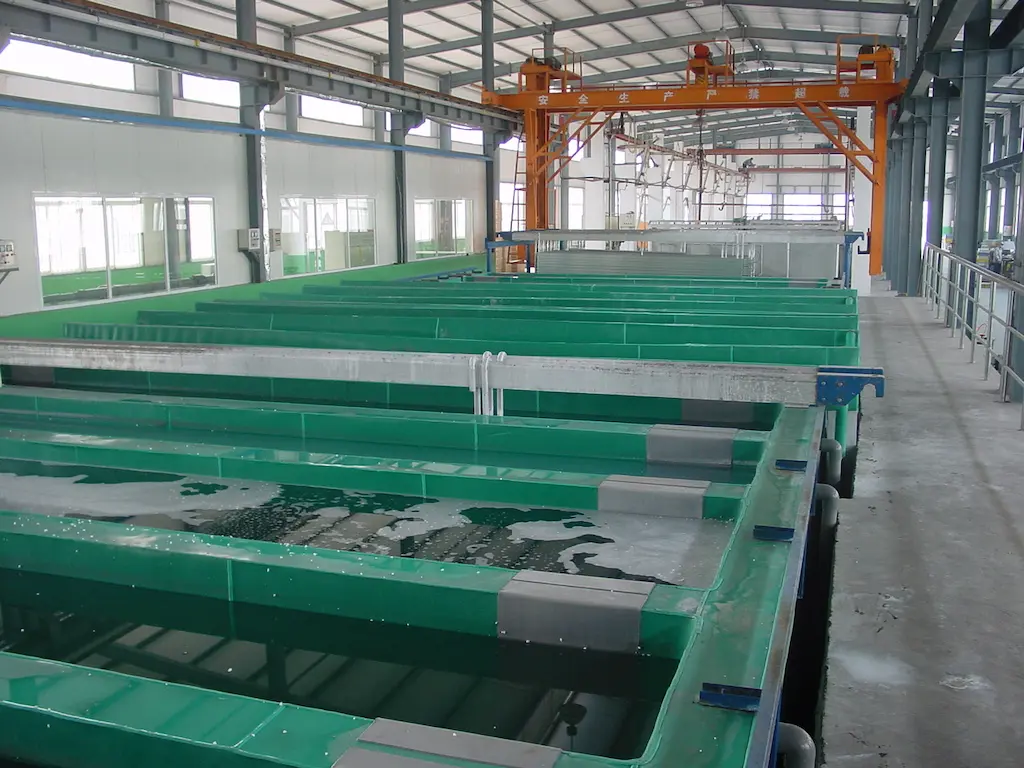

Anodizing is an electrochemical process in which aluminum is treated with an electric current in an acid bath. This creates a hard, controlled oxide layer that is firmly bonded to the base material. This layer protects against corrosion and offers significantly greater wear resistance than untreated aluminum.

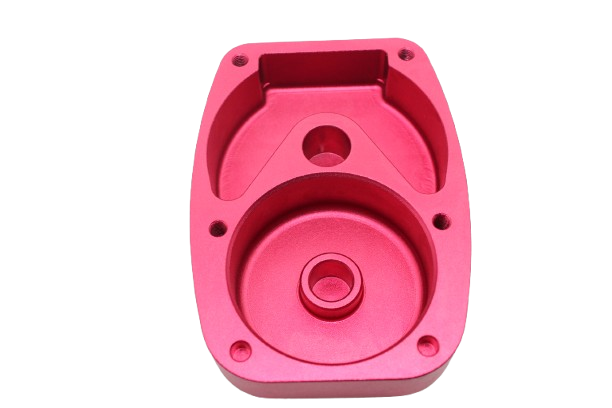

Thanks to the porous structure of the oxide layer, the surface can be colored in a variety of colors – from neutral grays to striking hues like red, blue, or gold. This makes anodizing ideal when technical performance and aesthetics must be combined.

TOS anodizes many extruded profiles , CNC-machined aluminum parts, and in some cases, forged work . Castings, such as gravity die castings or high-pressure castings, can often only be anodized to a limited extent due to their material density and alloy composition. For industrial applications with higher wear loads or extra layer thickness, TOS uses hard anodizing, which offers excellent insulating and mechanical properties.

At TOS Outsourcing, we manage the entire anodizing process: from pretreatment and layer selection to color finishing and quality control . Thanks to our network of specialized anodizing partners, we can anodize both small and large series efficiently, sustainably, and cost-effectively. This ensures a high-quality, long-lasting, and visually appealing finish for your aluminum parts.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start making a prototype.

After approval of the prototype, the assignment will begin.

For a client in the packaging industry, we produce complete, custom-made machine frames that serve as the foundation for high-quality....

For a client who supplies street furniture to municipalities, we developed a specially designed waste bin, fully adapted to intensive....

Anodizing is an electrochemical process in which aluminum is treated in an acid bath under an electric current. This creates a hard, wear-resistant oxide layer that is firmly bonded to the metal. This layer offers excellent protection against corrosion, wear, and weathering.

Unlike a coating, the anodized layer is not on top of the aluminum, but rather embedded in its surface, allowing the metal to retain its natural appearance. Anodizing aluminum therefore creates a durable, low-maintenance finish that is both technically and aesthetically pleasing.

Yes, aluminum can be color anodized. During the anodizing process, a porous oxide layer is created that can absorb colorants. This allows the surface to be finished in virtually any desired color—from classic silver and gray tones to striking colors like red, blue, gold, or black.

This method combines durability with design, making color anodizing popular for architectural applications, consumer products, and design elements. The color retains its beauty for a long time, even with heavy use or exposure to sunlight.

Hard anodizing is a special form of anodizing in which an extra-thick oxide layer is formed under controlled conditions. This layer offers very high wear resistance, excellent insulation, and protection against extreme conditions.

Hard anodizing is primarily used for industrial components, such as cylinders, machine parts, or technical profiles that are exposed to mechanical stress or high temperatures.

The combination of strength, insulation, and corrosion resistance makes hard anodizing the ideal choice for heavy-duty industrial applications.

Anodizing is suitable for a wide range of aluminum products. Consider:

Because the process is both protective and decorative, anodizing provides the perfect balance between functionality and aesthetics.

With TOS Outsourcing, you choose complete process management for aluminum anodizing. We ensure the correct pretreatment, anodizing layer, color selection, and quality control, tailored to your specific application.

Thanks to our international network of specialized anodizing partners in Poland and China, we can produce small and large series efficiently, cost-effectively, and in accordance with European quality standards.

Our advantages:

With TOS, you are assured of a high-quality, durable, and visually perfect anodized finish that significantly extends the lifespan and appearance of your aluminum products.