At TOS, you will find all disciplines for product development, manufacturing and finishing under one roof. We offer a wide range of production processes and surface treatments, supported by strong engineering and product optimisation. This enables us to deliver efficient, durable and cost effective solutions for every technical product.

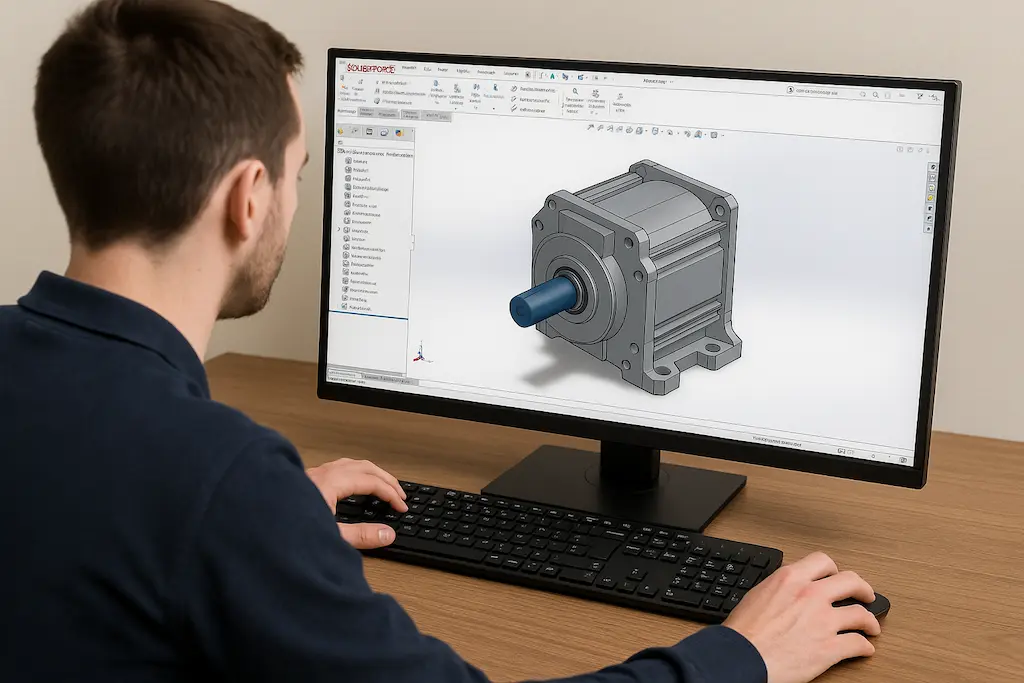

Our manufacturing partners specialise in CNC machining, casting, forging, pressing, welding, die casting and aluminium extrusion. Thanks to our experience with CAD design using SolidWorks and 3D printing, we quickly translate every idea into a manufacturable design and prototype.

For a high quality finish, we offer a wide range of surface treatments, including powder coating, anodising, e coating, galvanising, nickel plating and chrome plating. These treatments improve both the appearance and the corrosion resistance of your product.

We outsource the extrusion and processing of aluminium extrusion profiles for various customers in the Netherlands and Belgium, sometimes only cut to the required length and in other cases welded or further machined.

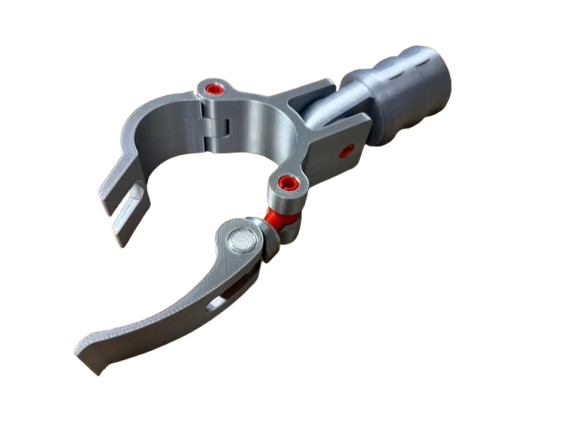

Lost wax casting is a precise casting process used to produce complex metal components with a high level of detail and an excellent surface finish. The method allows for tight tolerances and design freedom, making it ideal for high quality and technically demanding applications.

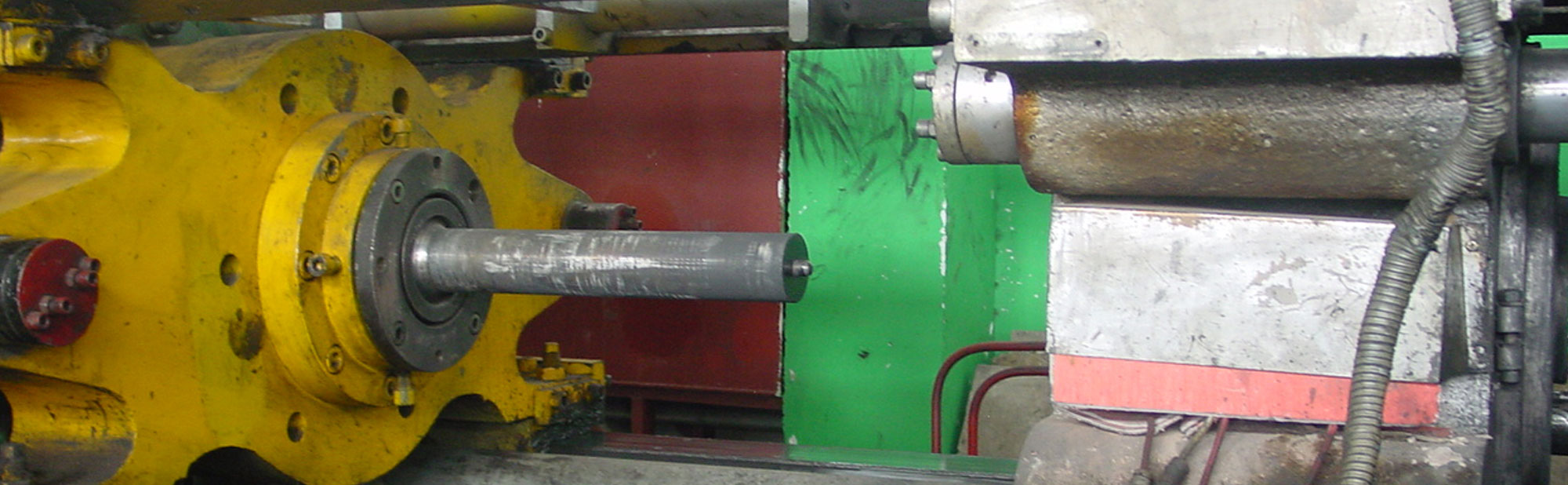

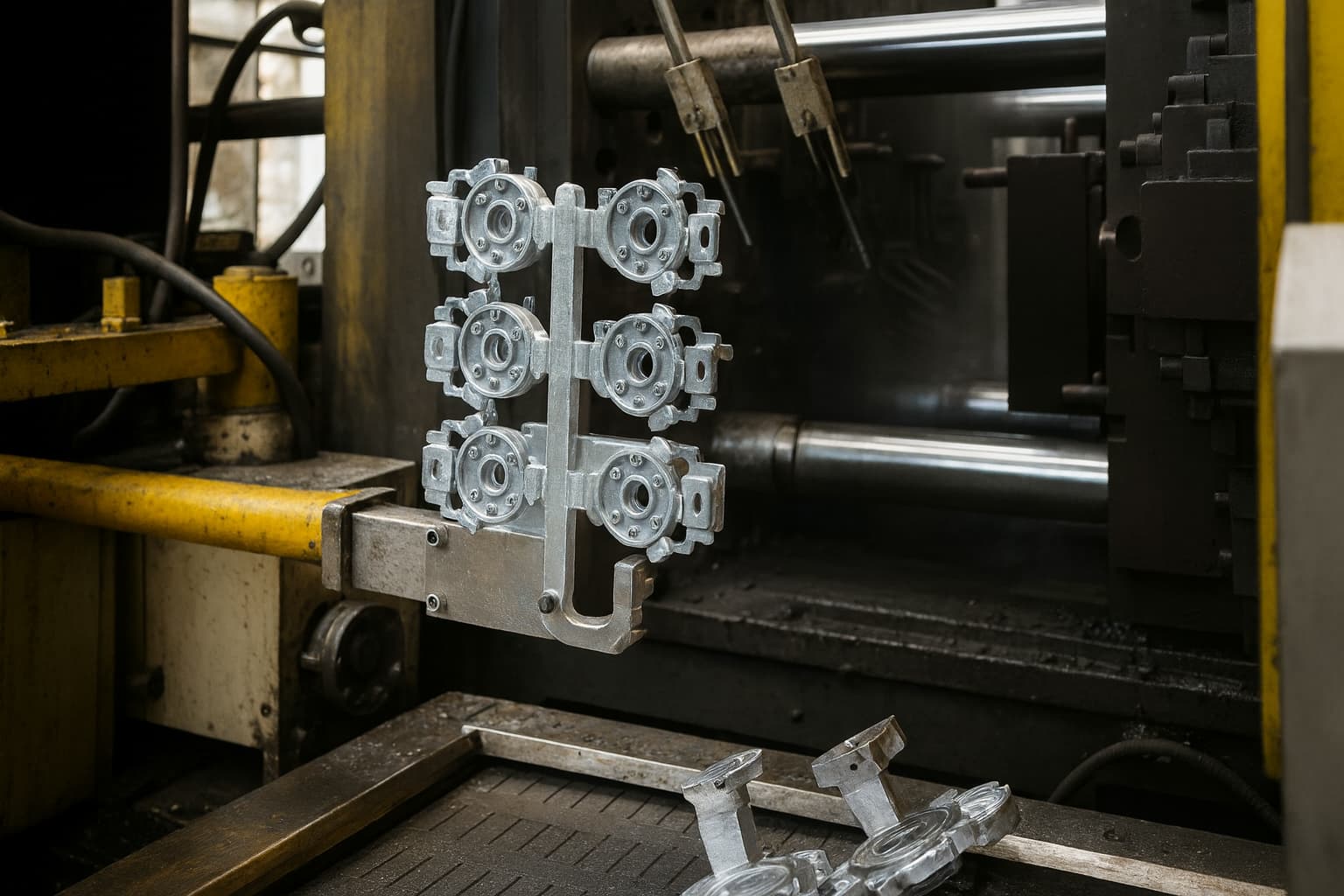

High pressure die casting (HPDC) is a highly efficient manufacturing technique for producing metal components with high accuracy and a smooth surface finish.

Gravity casting, also known as permanent mould casting, is a widely used method for producing metal components by allowing molten metal to flow into a permanent mould under the influence of gravity.

Sand casting is a versatile casting process in which molten metal is poured into a mould made of specially prepared sand.

Plastic injection moulding is the preferred method for efficiently producing accurate, complex and durable plastic components. During this process, molten plastic is injected under high pressure into a closed mould, where it cools rapidly and takes on the desired shape.

Welded constructions form the foundation of strong and durable metal products. At TOS, we design and manufacture custom welded structures with a strong focus on accuracy, material selection and welding techniques, from single pieces to full production series in accordance with European quality standards.

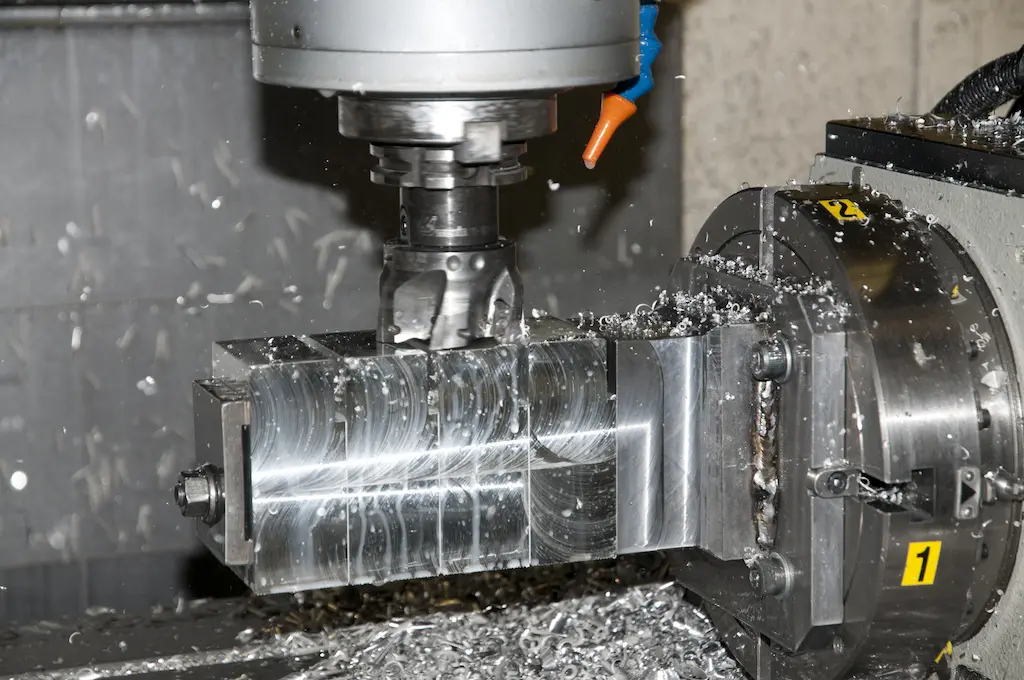

Machining is a broad group of processes in which material is removed using a cutting tool, creating chips and resulting in the desired shape.

Cutting is a machining process in which material is separated with high precision to achieve the desired shape. Depending on the material and thickness, techniques such as laser cutting, plasma cutting or waterjet cutting are used to produce clean edges and accurate contours.

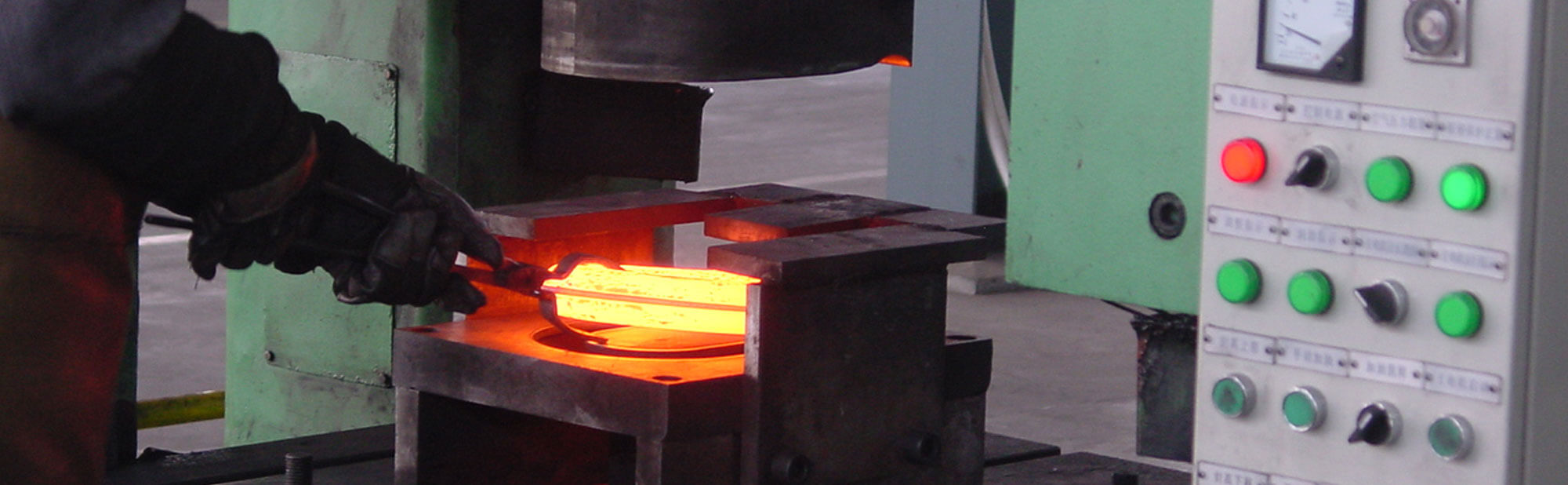

Forging is mainly used for components that require high tensile strength. Where casting is not a reliable method, forged parts can provide a suitable solution.

Deep drawing is a forming technique in which sheet metal is transformed into a seamless three dimensional shape through plastic deformation under mechanical or hydromechanical pressure.

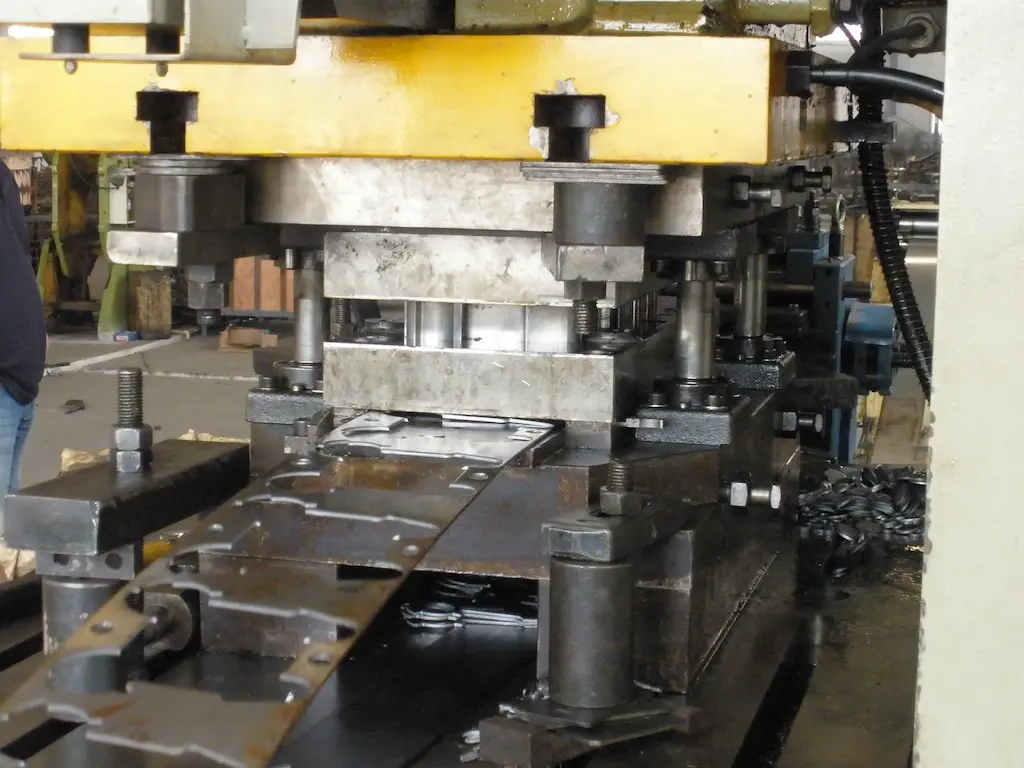

With progressive stamping, we produce accurate metal components by continuously punching and forming sheet material through a sequence of die steps. This technique is ideal for medium to very large production volumes, offering high dimensional accuracy and low cost per part.

Our assembly service ensures that individual components are combined into a complete and ready to use product. Whether it concerns simple subassemblies or complex final products, we provide an efficient and quality focused solution.

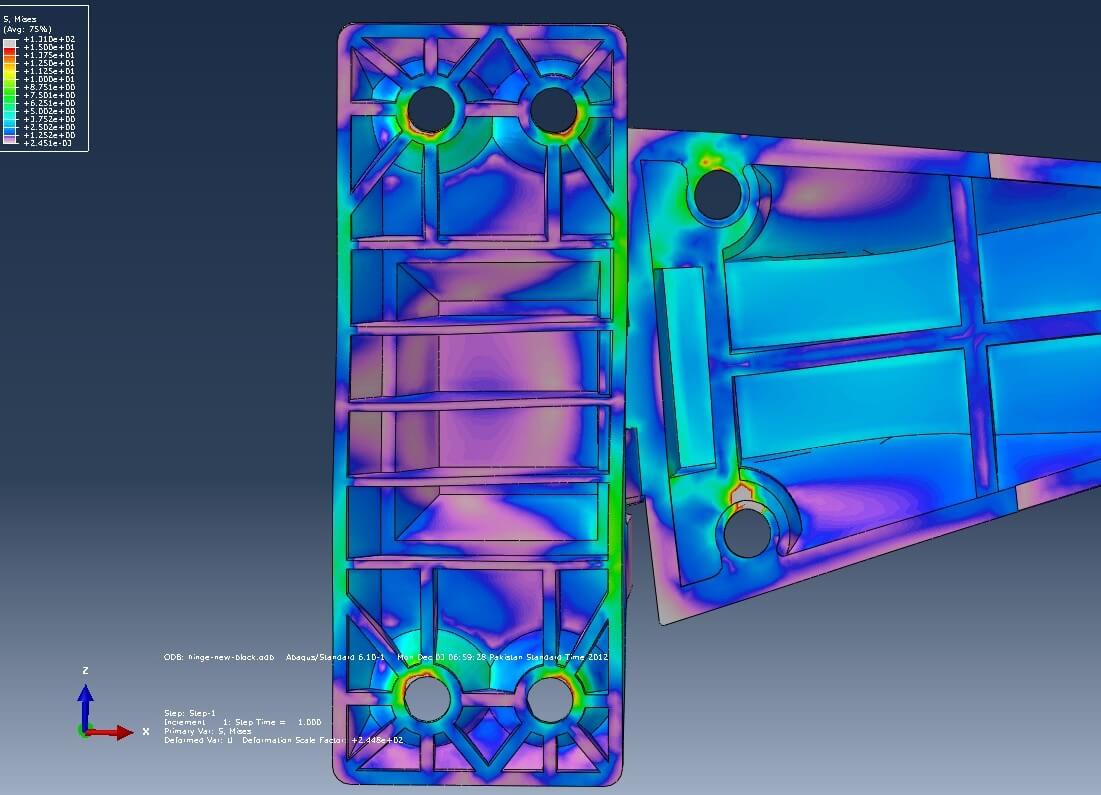

With our design optimisation service, we refine your product design so that it performs better, uses fewer resources and is ready for efficient production.

Our 3D design service brings your concept to life in an accurate digital model. Using modern CAD software, we create detailed 3D drawings that form the basis for prototyping, testing and production.

With our prototyping and 3D printing service, your 3D design is quickly transformed into a physical model. This allows you to test form, fit and functionality before investing in expensive production moulds or large series.

At TOS, quality is central to every project. We work with carefully selected manufacturing partners that comply with strict European quality standards. Every product is inspected for dimensions, material and finish to ensure it fully meets our customers specifications.

Powder coating is a high quality surface treatment in which an electrostatically applied powder layer is heated and cured to form a strong and even coating.

Wet painting is a traditional coating technique in which liquid paint is applied to a product and then cures into a protective and even layer. The result is a smooth and scratch resistant surface with excellent colour and gloss quality.

Blasting is a mechanical cleaning process in which an abrasive medium is blasted onto the surface under high pressure. It removes rust, old paint and other contaminants and creates a clean, rough surface that is ideal for a new coating or further processing.

Hot dip galvanising is a durable treatment in which steel or iron is immersed in a bath of molten zinc. The zinc forms a metallic layer that provides long term protection against rust and wear, even in harsh weather or industrial conditions.

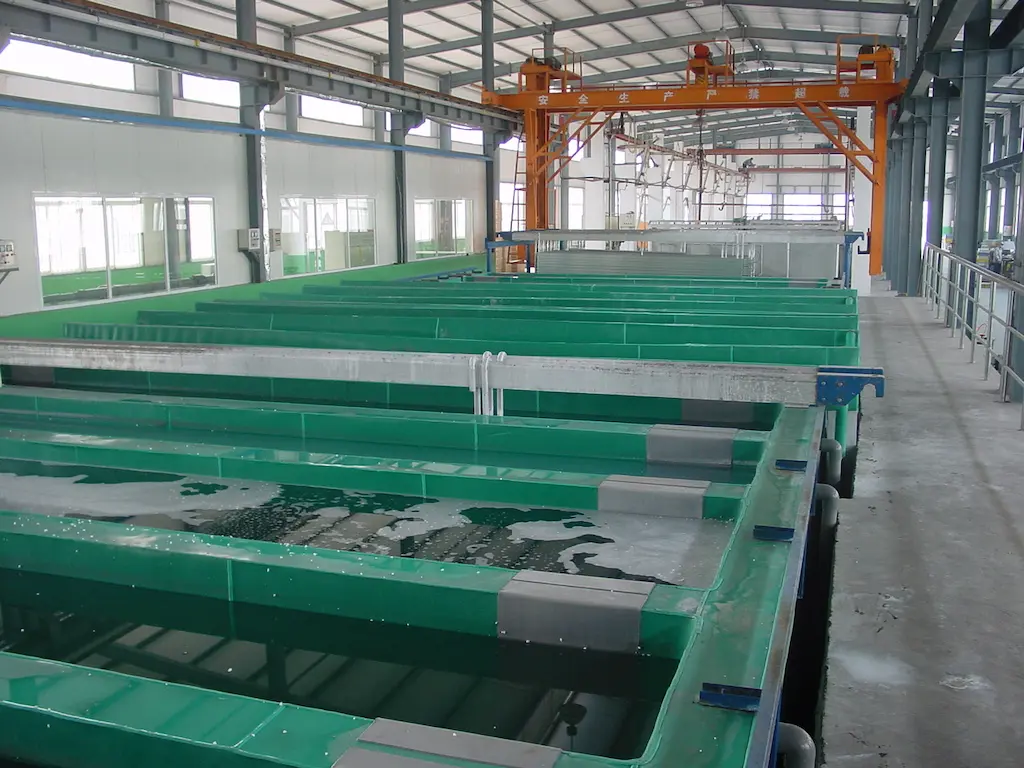

Electrolytic galvanising, also known as electroplating, is a process in which steel or iron is coated with a thin and even layer of zinc in an electrolytic bath. This coating protects the metal against corrosion and provides a smooth and glossy appearance that is ideal for visible parts and decorative applications.

Polishing is a mechanical finishing process in which metal is gradually ground and polished to achieve a mirror smooth and glossy finish. It not only improves the appearance but also reduces surface roughness and dirt adhesion.

At TOS Technical Outsource Solutions, we provide anodising for aluminium components. This electrochemical process creates a hard oxide layer on the surface that is wear resistant and corrosion resistant. Anodising can be carried out both transparent and in a wide range of colours, offering both functional and aesthetic benefits.

Chrome plating is the process in which a thin layer of chromium is applied electrolytically to a metal surface. The result is an extremely hard, corrosion resistant and mirror glossy finish. This chromium layer not only provides a premium appearance but also extends the service life of the underlying metal.

At TOS Technical Outsource Solutions, we offer electrocoating, also known as e coating, as a durable and uniform surface treatment. During this process, a water based coating layer is applied electrostatically to metal components and then cured in an oven.

Our production in Poland is an important part of our supply chain. Trucks depart weekly from our production locations to the Netherlands and Belgium. After loading, we usually deliver to the customer within 1 to 2 days.