Our quality control goes beyond simply inspecting and reporting. Within TOS’s international network, we work exclusively with production partners who hold recognized certifications, including ISO 9001 (quality management), ISO 3834 (quality requirements for fusion welding of metals), EN 1090 (CE marking for steel and aluminum structures), and IATF 16949 (automotive quality management).

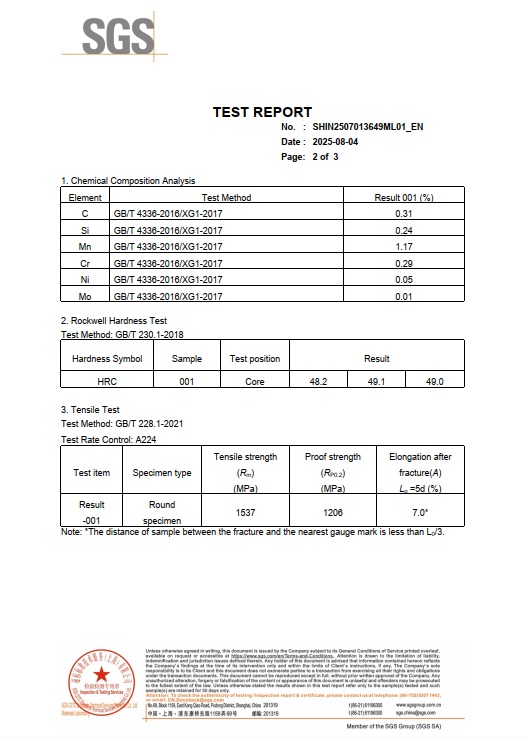

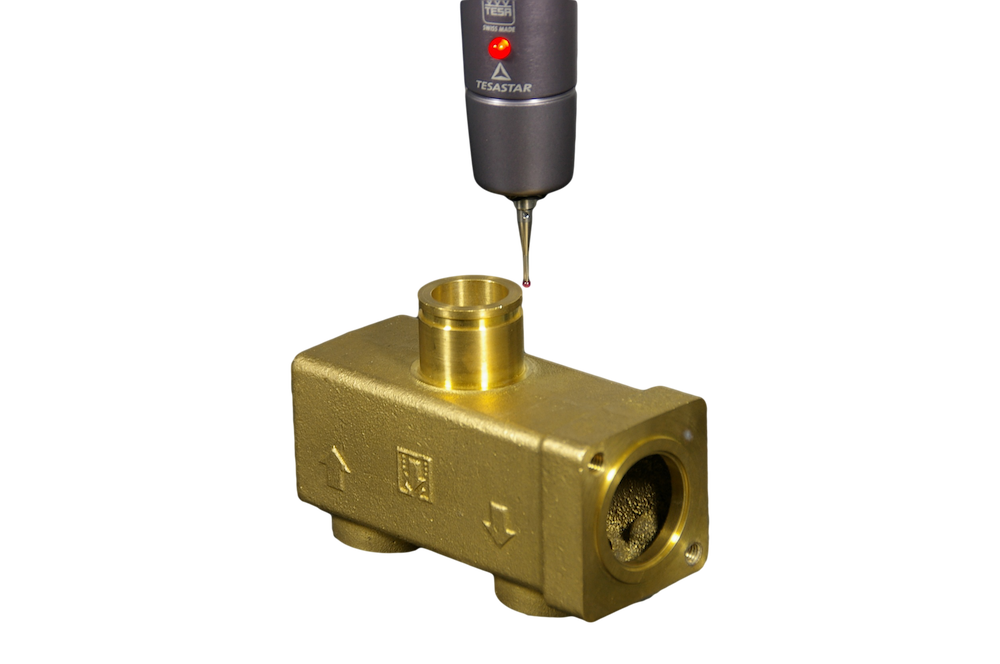

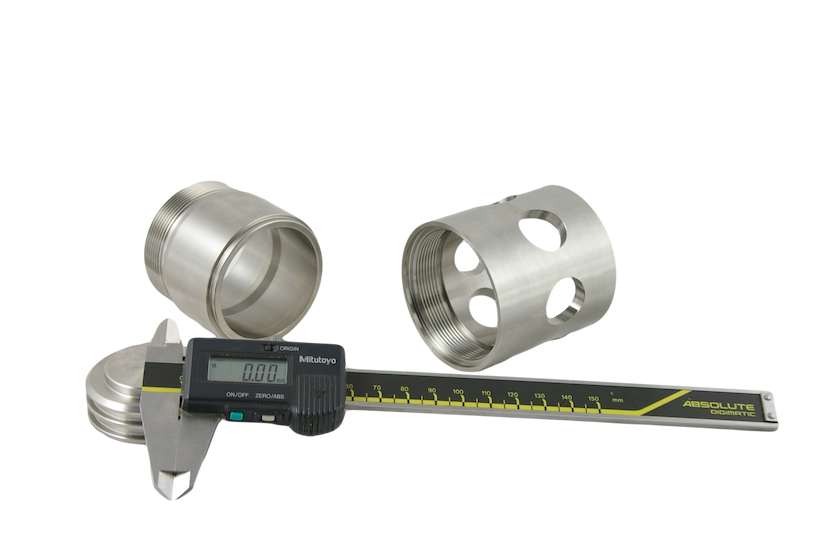

To ensure quality and traceability, we conduct rigorous checks in collaboration with SGS and other independent laboratories and inspection agencies. Depending on the project’s requirements, measurement reports, material certificates, and laboratory reports can be prepared and included with delivery. This way, you know exactly what you’re receiving – including demonstrable quality and the provenance of each component.

During this conversation we will briefly explain what we can do for you and answer your questions.

Based on your product and requirements, we request prices and delivery times from various suppliers.

We will then prepare a clear quote. Prices are quoted based on your terms and conditions.

Once you have approved our proposal, we will start creating a prototype.

After approval of the prototype, the assignment will begin.

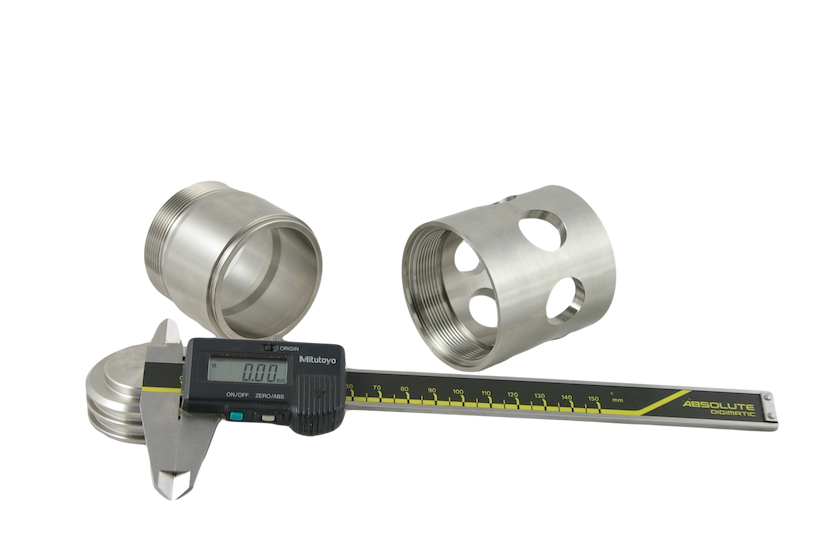

For a client in the cryogenics industry, we produce high-quality machined parts that must meet strict safety and temperature requirements.....

For a client in the packaging industry, we produce complete, custom-made machine frames that serve as the foundation for high-quality....